How To Install Air Duct Filter

Proper Installation of Furnace and Air-Handler Filters

Scope

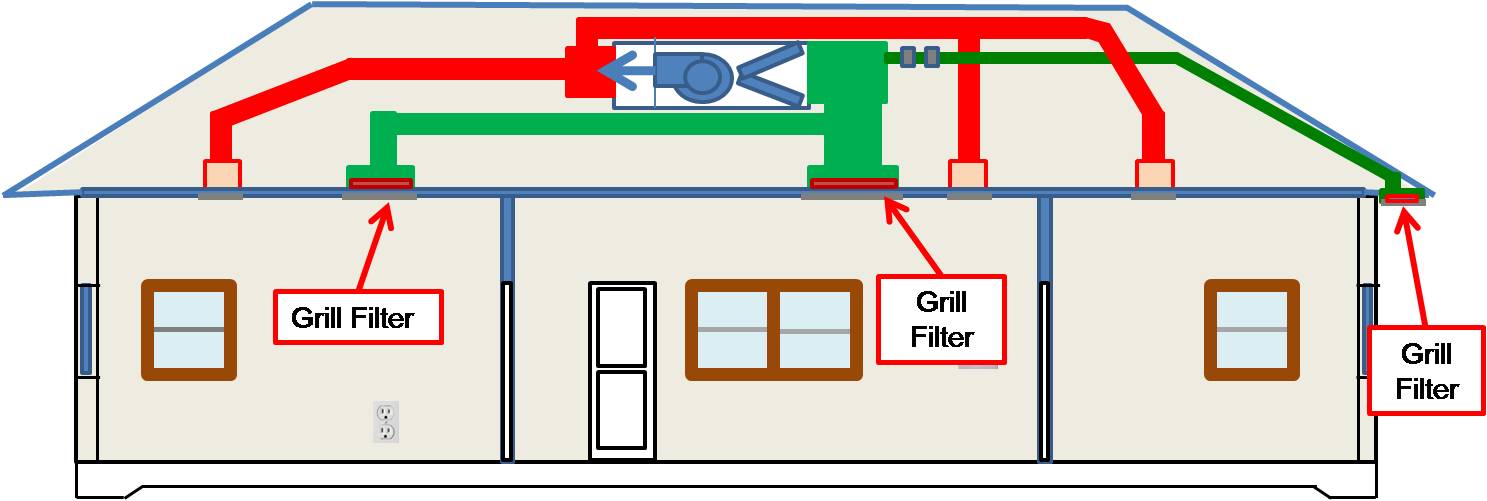

Install air filters on any ducted heating and cooling systems to filter air passing through the return air duct and outdoor air that is mechanically supplied to the air handler.

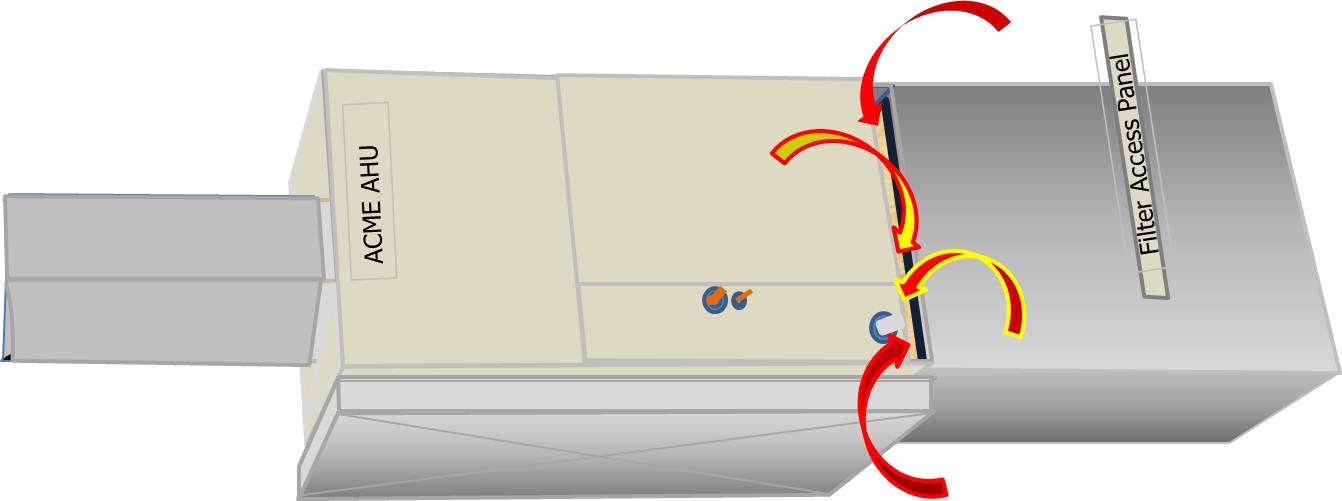

- Locate the filter where it can exist hands accessed by the homeowner for replacement or cleaning.

- If the filter is installed in a filter media box attached to the air handler, the access panel for the filter should be fitted with a flexible, air-tight gasket to forbid air leakage.

Run into the Compliance Tab for related codes and standards requirements, and criteria to see national programs such as DOE'southward Zero Energy Gear up Home program, Energy STAR Certified Homes, and Indoor airPLUS.

Description

Air filters are an important component of forced air HVAC systems. Filters are installed on the return side of the HVAC air handler to clean the air to protect the HVAC motor and to improve indoor air quality. Filters should too be installed in fresh air intakes to clean outside air that is brought into the domicile. Filters with higher MERV (Minimum Efficiency Reporting Value) ratings of MERV 6 or above can trap pollutants like pollen, dust mites, and mold spores. However, a dirty, clogged filter can dramatically reduce air catamenia, increasing furnace run time and increasing both wear on the motor and energy consumption. For optimum operation of both the filter and the HVAC equipment, the filters should be replaced or cleaned frequently. Therefore, the filters should be located in a place that is easily accessible for the domicile possessor.

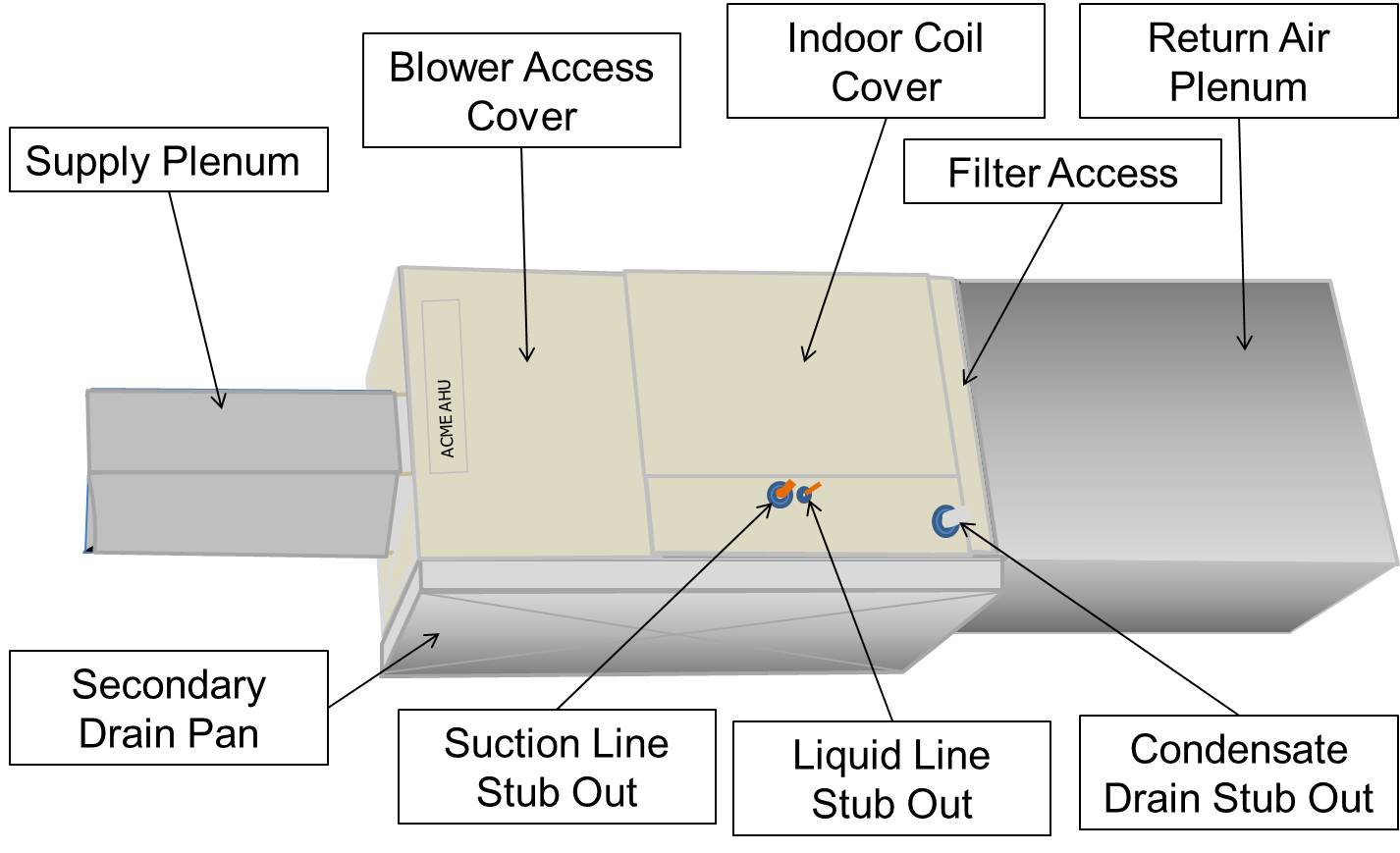

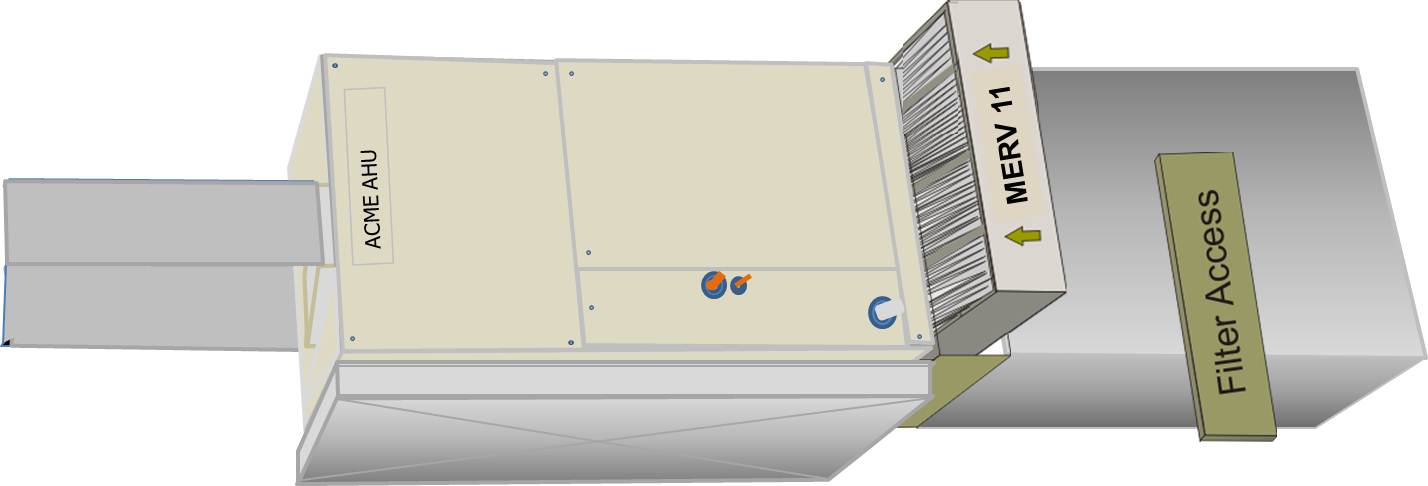

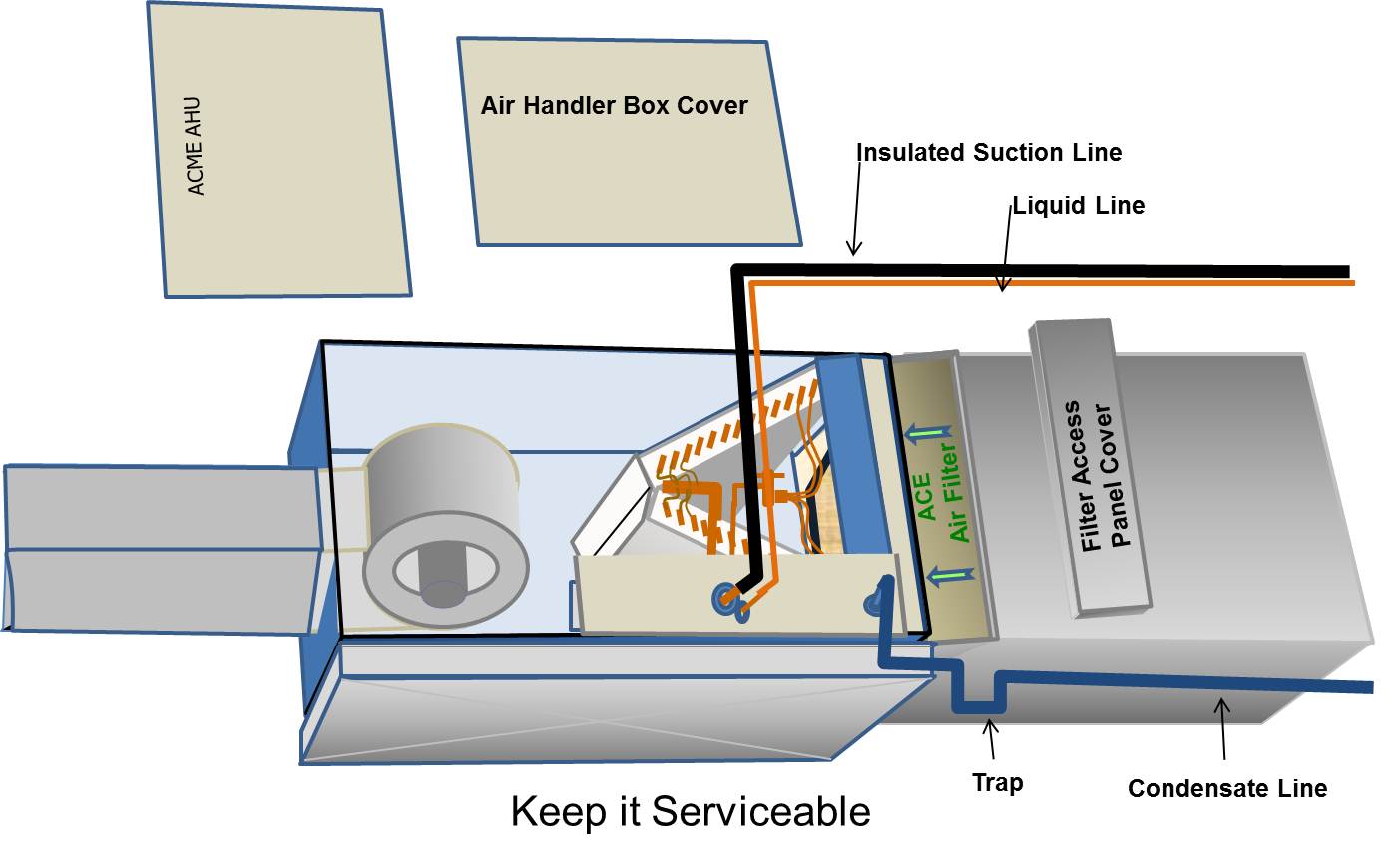

If the furnace air handler is in an attainable location (such equally a utility room, a basement, or an cranium with a pull-downwards staircase), the filter tin be installed in the air handler at the return plenum. The air handler box should be equipped with a filter media box that has a removable access panel cover that has a gasket for an air-tight seal when closed. The filter box might be prefabricated past the manufacturer or could be fabricated on site. The filter media frame should be appropriate for the size and type of filter desired. The filter dimensions and filter depth both influence filter capacity and air flow velocity. Filter sizing must be taken into business relationship when designing the HVAC arrangement to ensure that the HVAC system tin handle the associated force per unit area drib, particularly with high MERV filters. Increasing the filter surface area will subtract pressure drib; options for increasing surface expanse could include using more than deeply pleated filters or larger dimensioned filters. Filters must be sized using the Air conditioning Contractors of America (ACCA) Manual D (ANSI/ACCA 2009). For more information on furnace filter types, MERV ratings, and sizing, meet the guide Loftier MERV Filter.

If the furnace is in the cranium, the attic should be equipped with a staircase or pull-down stairs and a permanently installed walkway that the homeowner or service technician tin use to get to the furnace.

If the furnace air handler is located in an inaccessible location such equally a crawlspace or attic without a staircase, then the furnace filters should be located in the return grilles, with a filter located in each return grille.

If the home is equipped with a fresh air intake that is ducted to the air handler, a filter should be installed at the fresh air intake and the fresh air intake should be located where it is accessible so the filter can be replaced or cleaned as needed.

How to Install a Filter in a Furnace Air Handler

1. Fabricate and install a filter media box on site. Install the filter media box between the return air plenum and the air handler box. Or, buy an air handler that includes a pre-made filter box. Ensure that the box is the correct size for the filter to be installed. Filters must be sized using ACCA Manual D (ANSI/ACCA 2009). Improperly sized filters can cause mechanical failure.

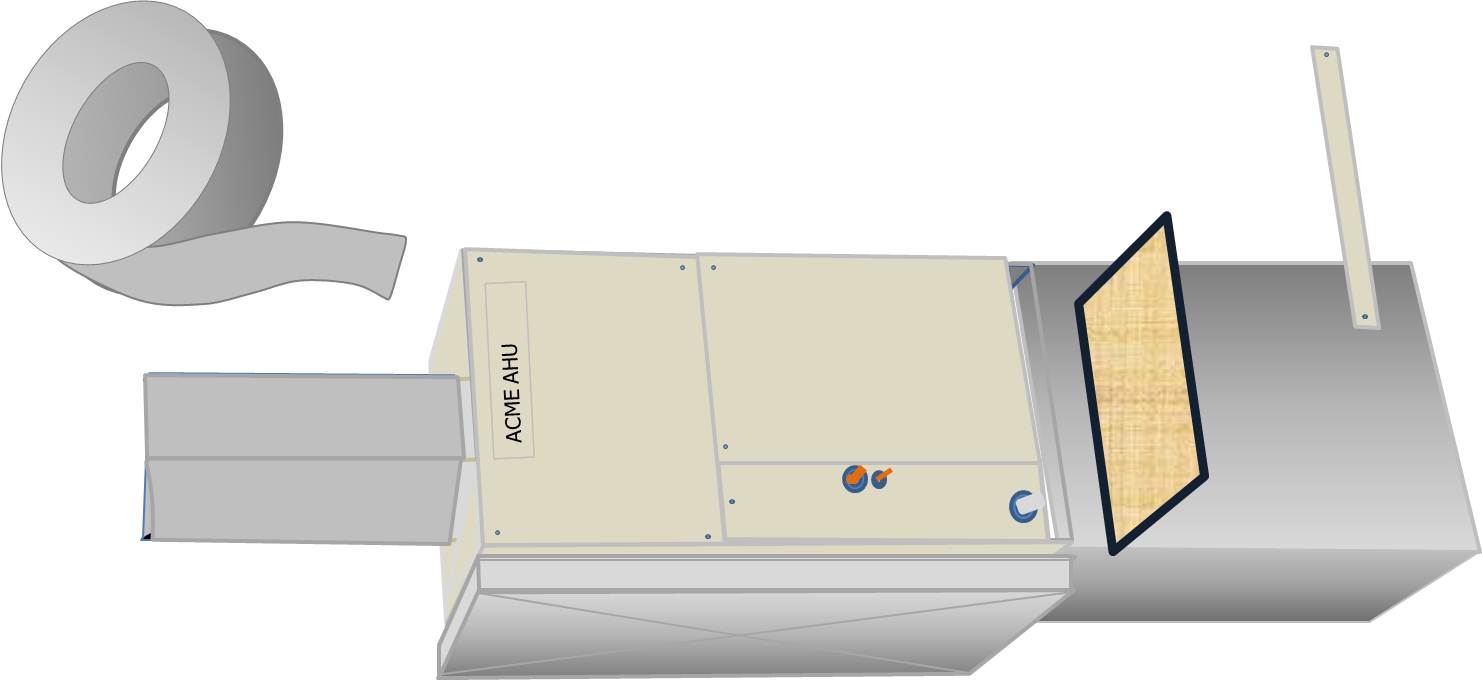

two. Slide the filter into the slot and identify the filter access panel comprehend over the opening. The panel cover should have a gasket to ensure an air-tight seal. The cover tin exist attached at the edges with duct record or magnetic tape, which provides additional air sealing and can be hands removed when the filter is checked for cleaning or replacement. If the filter comprehend is left off or unsealed, the air handler tin can pull unconditioned and/or unwanted air into the home. Leakage at the filter cover tin contribute to poor indoor air quality if the air handler is located in a garage or other areas where the air quality is non desirable.

3. Complete air handler installation past installing wiring and condensate piping. Ensure that pipage and wiring do not block access to the filter.

How to Install a Filter at the Return Grille

i. If the furnace is in a location that is difficult for the homeowner to access (for instance, a crawlspace or an attic that does not have stairway or drop-down stairway access), then install filters inside the return grilles in the home.

2. Ensure that grilles can be opened from inside the home. Install grilles that tin be removed safely, for example, grilles that are fastened by a hinge along 1 side to minimize the risk that they will accidentally fall down while being opened.

3. Install MERV six or college filters that friction match the sizing designation specified by the HVAC designer in accord with Manual D (ANSI/ACCA 2009). Do not install filters with MERV ratings higher than that for which the HVAC organization was designed. Higher-than-specified MERV filters will increment air resistance, increasing energy usage and peradventure contributing to equipment failure. For more nearly filter sizing, see High MERV Filter.

How to Install a Filter at the Fresh Air Intake

-

Choose a location to install the outside air intake, such every bit a porch ceiling or eave, that is away from polluting sources and easily accessible to the domicile possessor to facilitate filter replacement (meet Figures 2 and 9). For more on outside air intake locations, meet Ventilation Air Inlet Locations.

-

Cutting a pigsty for the air intake with dimensions similar to the grille and the filter to be installed. When selecting a filter size and MERV rating, consider air flow resistance because the pressure drop of this outdoor air intake duct and filter must be included in the Manual D calculations when designing the entire HVAC duct organisation. A MERV 6 filter should be adequate.

-

Install a register box (kick) to which the duct volition be attached. Almost register boxes are at least iv inches deep. This space will keep the duct terminus from touching the filter. Assuasive several inches of distance between the filter and the duct terminus helps to decrease the velocity of the air flow through the filter and too ensures that the total surface area of the filter is used, which will meliorate filter performance and increase filter life.

-

Install a hinged grille at the exterior of the fresh air intake opening (meet Figure 8).

-

Install wire mesh insect and bird screen.

-

Place the filter on the interior side of the grille and close the grille.

-

Include instructions informing the homeowner to check this filter periodically for replacement with a similar MERV-rated filter.

-

If the exterior air intake must exist located in an inaccessible location, construct and install a filter media frame in a filter box that is positioned in an accessible place at the duct connection to the air handler return air plenum or somewhere along the fresh air intake duct that is accessible to the home owner.

Ensuring Success

In homes with ducted HVAC equipment, the HVAC contractor should specify and install furnace filters at the render plenum of the air handler or at all return grilles and on whatever outdoor air intakes. The HERS rater should inspect to make sure that the filters are installed correctly. If the filter is installed at the furnace, inspect that a filter media box has been installed to firm the filter and that this box has an admission panel with a gasket to forestall air leakage.

Climate

No climate-specific data applies.

The Compliance tab contains both plan and code information. Code language is excerpted and summarized beneath. For verbal lawmaking language, refer to the applicable lawmaking, which may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you lot notice broken links.

ENERGY STAR Certified Homes, Version iii/three.1 (Rev. 09)

National Rater Field Checklist

ix. Filtration

9.1 At least one MERV 6 or college filter installed in each ducted mechanical system in a location that facilitates access and regular service by the possessor.53

nine.2 Filter admission console includes gasket or comparable sealing mechanism and fits snugly confronting the exposed edge of filter when airtight to forestall bypass.54

ix.3 All return air and mechanically supplied outdoor air passes through filter prior to conditioning.

Footnote 53) Based upon ASHRAE 62.two-2010, ducted mechanical systems are those that supply air to an occupiable space with a full amount of supply ductwork exceeding 10 ft. in length and through a thermal conditioning component, except for evaporative coolers. Systems that do not meet this definition are exempt from this requirement. While filters are recommended for mini-dissever systems, HRV's and ERV'due south, these systems, ducted or not, typically practise non have MERV-rated filters available for employ and are, therefore, also exempted under this version of the requirements. HVAC filters located in the attic shall exist considered accessible to the occupant if either 1) drop-downwards stairs provide access to attic and a permanently installed walkway has been provided between the attic access location and the filter or 2) the filter location enables arm-length access from a portable ladder without the need to step into the attic and the ceiling meridian where access is provided is ≤ 12 ft.

Footnote 54) The filter media box (i.east., the component in the HVAC arrangement that houses the filter) may be either site-made by the installer or prefabricated past the manufacturer to meet this requirement. These requirements only use when the filter is installed in a filter media box located in the HVAC system, non when the filter is installed flush with the render grill.

Please see the Free energy STAR Certified Homes Implementation Timeline for the program version and revision currently applicable in in your state.

DOE Zero Free energy Ready Home (Revision 07)

Exhibit ane Mandatory Requirements.

Showroom 1, Particular 1) Certified under the Free energy STAR Qualified Homes Program or the ENERGY STAR Multifamily New Construction Plan.

Showroom one, Particular six) Certified under EPA Indoor airPLUS.

EPA Indoor airPLUS (Revision 04)

4.vii Filtration for Central Forced-Air HVAC Systems. Install just HVAC filters that are rated MERV 8 or higher co-ordinate to ASHRAE 52.ii-2007 (at approximately 295 fpm).

Advisory: EPA recommends, but does not crave, filters rated at MERV thirteen or higher to reduce exposure to fine particles. Filters perform best when the filter rack pattern includes the following features, which are also included in some manufacturers' filter media boxes:

- Flexible, air-tight (eastward.g., closed-jail cell cream) gasket material on the surface that contacts the air-leaving (downstream) side of the filter.

- Friction fit or spring clips installed on the upstream side of the filter to hold information technology firmly in place.

- Upon installation of the air handling unit, include a filter for the remainder of construction activeness to protect the unit of measurement and/or coil from construction debris and dust. Filter should be clean upon final inspection following construction (see Specification 7.1). Advisory: To reduce the likelihood of construction grit contaminating the ducts and air handler, limit apply of the HVAC system during activities with increased dust (east.m. drywall sanding, flooring sanding).

- Do not install whatever air-cleaning equipment designed to produce ozone (i.e., ozone generators).

2017 California Title 24 Building Energy Efficiency Standards

The 2017 California Championship 24 Edifice Energy Efficiency Standards crave all HVAC filters to be MERV half-dozen or greater. Filter media that provide at least l% particle efficiency in the three.0- to 10-µm range according to AHRI 680 are considered to meet the MERV 6 criterion. HVAC filters are required to suit to the pattern pressure drop specification on the return grille label.

2017 California Appliance Efficiency Emergency Rulemaking for Residential Air Filters

The California Energy Commission has proposed to amend the California Code of Regulations, Title 20, Sections 1606, Table 10, and 1607(d)(12) to filibuster the date by when residential air filters for employ in forced-air heating or forced-air cooling equipment that are sold or offered for sale in the State of California must comply with the mandatory testing, certification, and marker requirements in the apparatus efficiency regulations, from July 1, 2016, to Apr one, 2019.

American Lung Association

The American lung Association Health House® guidelines require filters to have a minimum rating of MERV 11 (ALA 2012).

American Order of Heating, Refrigeration and Ac Engineers (ASHRAE) Standard 52.2-2017 - Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size

Standard 52.ii establishes a method of laboratory testing to measure the performance of general ventilation air-cleaning devices in removing particles of specific diameters.

ASHRAE Standard 62.ane-2016 –Ventilation for Adequate Indoor Air Quality

ASHRAE Standard 62.1 sets specifications and measures for ventilation system design and indoor air quality.

ASHRAE 62.2-2010, ASHRAE 62.2-2013, and ASHRAE 62.2-2016

ASHRAE Standard 62.2 sets specifications and measures for ventilation system blueprint and indoor air quality in depression-rise residential buildings.

American National Standards Institute (ANSI)/Ac, Heating and Refrigeration Institute (AHRI) Standard 680, 2009 Standard for Functioning Rating of Residential Air Filter Equipment

Standard 680 establishes definitions, classifications, examination requirements, data requirements, ratings, operating requirements, marking and nameplate data and conformance weather for residential air filter equipment.

Existing Homes

Scope

Supplant the air filters in ducted heating, ventilation and ac (HVAC) equipment with new filters having a MERV rating of 6 or higher and a resistance to airflow that does not exceed the allowable pressure level drop for the HVAC arrangement.

- Cheque the condition of the HVAC filters. If the filters are loaded with particulates, supercede with new, higher MERV filters when performing HVAC-related home functioning upgrades and when responding to comfort complaints. Make certain the new filters practise not exceed the allowed pressure driblet for the HVAC system.

- If the homeowner requests a loftier-MERV (or HEPA) filter, verify the pressure drop will still exist within acceptable limits.

- Provide homeowners with data for future filter replacement, such as the date of the next filter replacement, designed pressure drop for the filter, and installation instructions.

- Follow safe piece of work practices equally described in the U.S. Department of Free energy's Standard Piece of work Specifications when replacing and treatment HVAC filters and inspecting air handlers.

Clarification

How to Install and Specify High-MERV Filters in an Existing Dwelling house

- At the HVAC equipment, place the return grille characterization, if available. Write down the initial resistance (inches h2o cavalcade, inch westward.c.) of the HVAC filter at the design airflow rate (cubic-feet per minute, cfm).

- Go to each HVAC filter location and write down the dimensions of the existing filters. If in that location are air gaps effectually any of the filters, and so use a measuring tape to decide the appropriate dimensions.

- When purchasing or ordering new HVAC filters, utilize the resistance-to-airflow specified on the return grille label to buy a replacement with the advisable resistance-to-airflow. If the return grille label doesn't exist and specified filter resistance-to-airflow for the HVAC equipment is unavailable, effort to decide the resistance-to-airflow of the spent filter (either on the filter, or via internet or retail sales person). If no information is available for the resistance-to-airflow, consider purchasing the aforementioned or a similar model of HVAC filter equally the spent filter. Use the filter dimensions you've written downwardly to ensure the replacement is the proper size. Identify filters with a MERV rating of half dozen or higher. If possible, select a filter with the static pressure measurements listed on the packaging or online.

- Once y'all've caused new HVAC filters, notation the installation engagement and recommended replacement date on the edge with permanent marker then the homeowner can track the replacement cycle. Also notation the MERV level and the specified air filter resistance-to-airflow if these are not already printed on the filter.

- Turn off the HVAC equipment or set the thermostat and then it won't operate while replacing the filters.

- Remove the spent filters from the ducted HVAC equipment.

- When installing the new HVAC filters, remove the plastic wrap merely practice not remove the cardboard framing. Identify the airflow arrow and marshal the filter so the arrow points toward the HVAC equipment in the return duct or return annals grille.

- Insert the HVAC filter into the designated slot.

- Restore any levers, gaskets, seals, or grilles to their advisable status.

- Plough the HVAC equipment back on or return the thermostat to the appropriate temperature.

- Contractors, show homeowners how to replace their HVAC filters and advise that they exist replaced every three months, or more oftentimes if needed, particularly in homes with HVAC equipment that runs 6 to twelve months per year, with 4 or more occupants, pets, smoking indoors, allergic occupants, or construction taking place within or outside the habitation. Show the homeowner the installation date and recommended replacement engagement noted on the filter frame.

- Contractors, advise homeowners to cheque HVAC filters periodically. Filters should be replaced immediately if the filters are chock-full with droppings, have collapsed fins, are making a banging racket when the organization comes on, or are damp or moldy.

Access to some references may require buy from the publisher. While we continually update our database, links may have inverse since posting. Please contact our webmaster if you discover broken links.

References and Resources*

*For not-dated media, such as websites, the date listed is the engagement accessed.

Contributors to this Guide

The following authors and organizations contributed to the content in this Guide.

Mobile Field Kit

The Building America Field Kit allows you to salve items to your profile for review or use on-site.

Sign Up or Log In

Did you find this information helpful?

How To Install Air Duct Filter,

Source: https://basc.pnnl.gov/resource-guides/proper-installation-furnace-and-air-handler-filters

Posted by: beasleydody1988.blogspot.com

0 Response to "How To Install Air Duct Filter"

Post a Comment